- РУССКИЙ

- Очистительная линия

- SE-MK Трубчатый магнит

- SE-GS Зерновой сепаратор

- SE-SS Зерновой сепаратор Saymn

- SE-AC Аспирационный канал

- SE-ART Тарар с рециркуляцией воздуха

- SE-DS Камнеотборник

- SE-DC Камнеотборник 2 этажный

- SE-TR Триер

- SE-IS Oбоечная машина

- SE-DT Вихревой увлажнитель

- SE-DWTR Увлажнительная машина

- SE-RA Круговои ceпаратор

- SE-SO Обоечная машина Turbo

- SE-MK Cепаратор высокого объема

- SE-MMF Multinator кaмнeoтбoрник

- SE-MXM Kвадратный Mагнит

- SE-LP Вентилятор низкого давления

- Размольная линия

- SE-QP Квадратный рассев

- SE-TCS Малогабаритный рассев

- SE-SCS Подвесной контрольный рассев

- SE-CS Напольный раскачивающийся контрольный рассев

- SE-PR Ситовеечная машина

- SE-RM Четырех- и восьмивальцовые станки

- SE-HV Горизонтальное виброционное сито

- SE-BF Вымольная машина

- SE-DD Барабанный деташер

- SE-İD Энтолейтор

- SE-VF Вибропитатель

- SE-HP Вентилятор высокого и низкого давления

- SE-VS Вертикальное вибрационное сито

- SE-AT Увлажнитель автоматический

- SE-İD Уничтожитель насекомых

- SE-SU Стол для натяжения ситоткани

- SE-VMD Bитаминизатор

- SE-DD Виброразгрузитель для муки, зерна и отрубей

- Раздел траспортировки

- SE-AC Шлюзовый затвор и циклон

- SE-EC Эклюс

- SE-BW Бловер

- SE-CC Транспортёр цепной в коробе

- SE-TS Трубчатый винтовой конвейер

- SE-CY Пылевой циклон

- SE-PL Клапан перекидной

- SE-AJ Фильтры

- SE-FSC Линия по перевозке продукта

- SE-MS Моно Циклон

- SE-SG Пневматический и мануальный затвор

- SE-SC Шнековый конвейер

- SE-BE Элеватор

- SE-SFF Квадратный фильтр

- SE-ZE Z образная нория

- Фасовочная линия

- SE-MP Упаковочная машина на 5,10 кг мука пакет

- SE-MP Упаковочная машина на 25,50 кг пакет мука

- SE-FM Упаковочная машина на 25,50 кг пакет мука однократное наполнение и двойное опустошение

- SE-AH Поточные весы

- SE-EH Цилиндрические поточные весы

- SE-FB Дозатор зерна

- SE-BC Упаковочная машина для муки карусельного типа

- SE-ZX Распределитель муки

- SE-VTM Клапанная система погрузки в мешки

- Машины для комбикормовых заводов

- Запасные части

- Электрическая автоматизация

- Проекты мукомольных заводов

- Монтажное оборудование

- Здания из стальных конструкций

- Cилосы для муки и зерна

- Очистительная линия

- English

- Cleaning section

- SE-MK Magnet Tubular Type

- SE-GS Grain Seperator

- SE-SS Saymn Seperator

- SE-AC Air Canal

- SE-ART Air Recycling Tarar

- SE-DS Dry Stoner

- SE-DC Destoner Classifier

- SE-TR Trieur

- SE-IS Intensive Scourer

- SE-DT Dampener Turbolizer

- SE-DWTR Dampener With There Rotor

- SE-RA Round Aspırator

- SE-SO Scourer

- SE-MK Heavy Cleaning Separator

- SE-MMF Multınator Mıxed Flactıon-CalssIfler Destoner

- SE-MXM Square Magnet

- SE-LP Low Pressure Fan

- Milling Section

- SE-QP Quadro Plansifter

- SE-TCS Two Channel Sifter

- SE-SCS Single Channel Sifter

- SE-CS Control Sifter

- SE-PR Purifier

- SE-RM Roller Mill

- SE-HV Horızontal Vıbro Sıfter

- SE-BF Bran Finisher

- SE-DD Drum Detacher

- SE-İD Impact Detacher

- SE-VF Vibro Feeder

- SE-HP High Pressure Fan

- SE-VS Vibro Sifter

- SE-AT Automatic Tempering Machine

- SE-İD Infestation Destroyer For Flour

- SE-SU Stretching Unit

- SE-VMD Vitamin Machine Dosing

- SE-DD Drum Dıscharger For Flour and Bran

- Transportation Group

- SE-AC Aırlock And Pneumatıc Cyclone

- SE-EC Ecluse

- SE-BW Blover

- SE-CC Chain Conveyor

- SE-TS Tubular Screw Conveyor

- SE-CY Cyclone

- SE-PL Pneumatic Line Diverting Gate

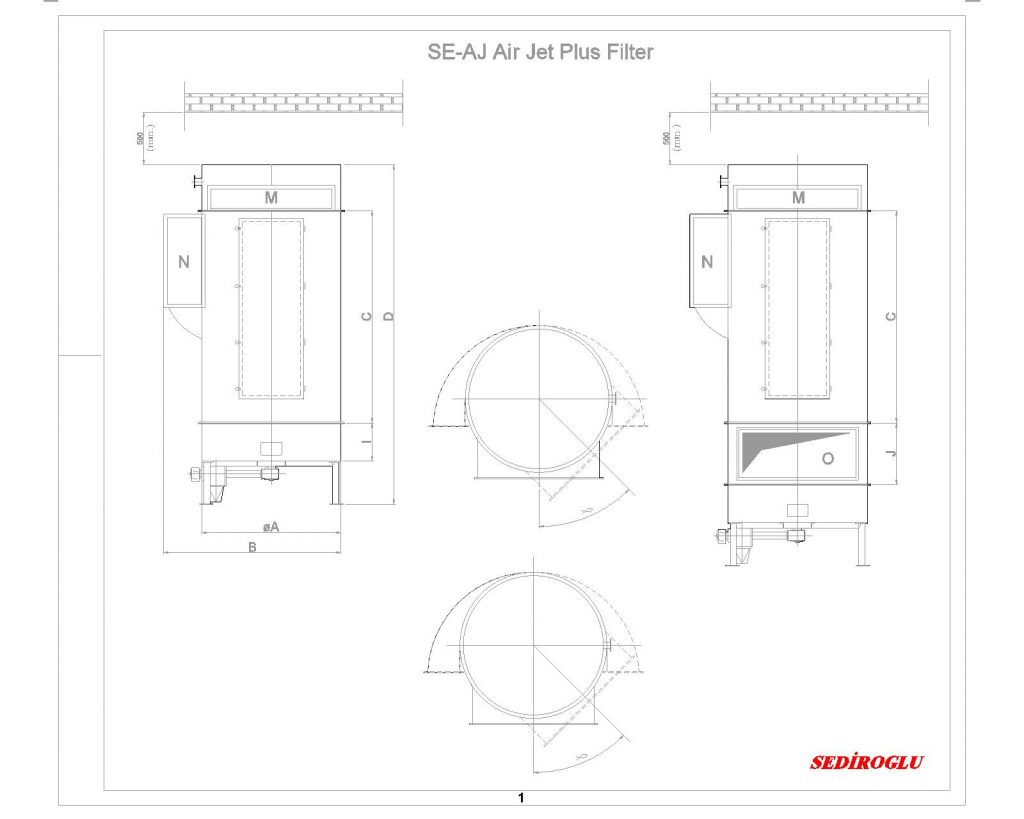

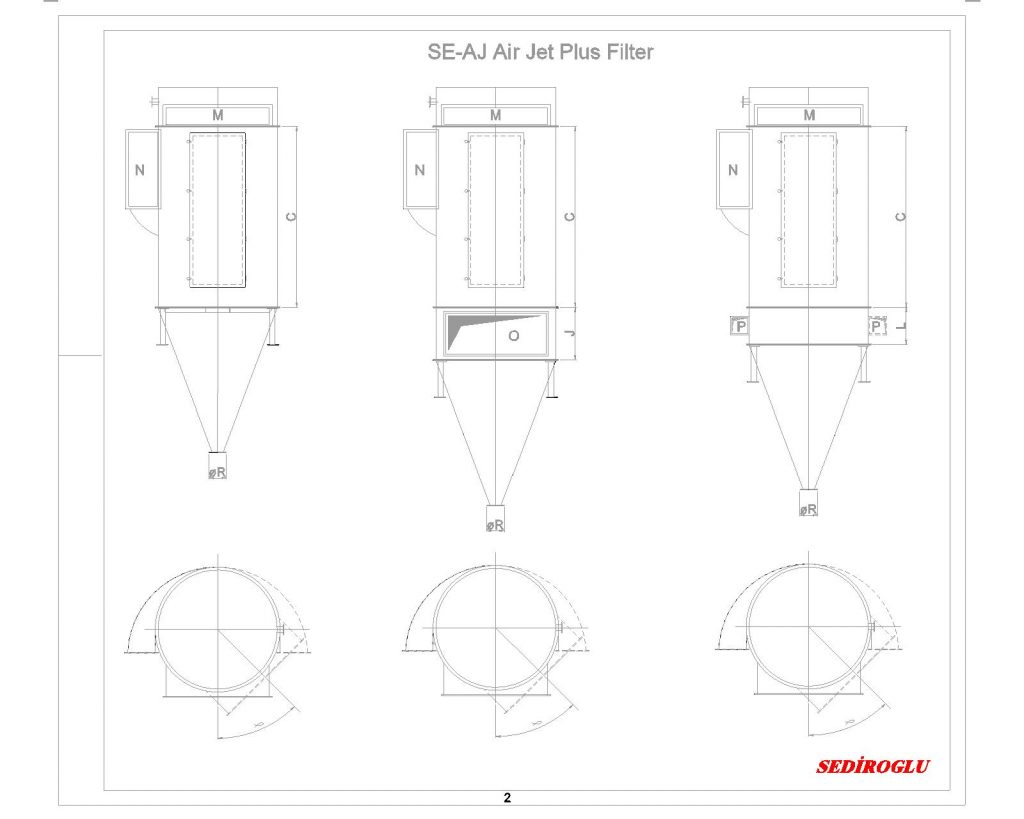

- SE-AJ Air Jet Plus Filter

- SE-FSC Flour Screw Conveyor

- SE-MS Mono Siklon

- SE-SG Slıdıng Gate

- SE-SC Screw Conveyor

- SE-BE Bucket Elevatör

- SE-SFF Square Filter

- SE-ZE Z Elevatör

- Packing Section

- SE-MP 1 Mouth Packing Machine 5 kg – 10 kg

- SE-MP 1 Mouth Packing Machine 25 kg – 50 kg

- SE-FM Flour Bagging Machine System With Double Weigh Hopper & Single Station 25/50 Kg

- SE-AH Automatic Hopper Scale

- SE-EH Extraction Rate Scale

- SE-FB Flow Balancer

- SE-BC Bagging Carousel

- SE-ZX flour distributor

- SE-VTM Valve Type Flour Bagging Machine

- Spare Part

- Electrical Automation

- Flour Factory Projects

- Flour Flow Pipe

- Steel Factory Projects

- Flour and Wheat Silos

- Cleaning section

- ESPAÑOL

- Sección de Limpieza

- SE-MK Aparato Magnético Tubular

- SE-GS Vıbro Sılo Eyecyor

- SE-SS Separador Saymn

- SE-AC Separador Aerodinámico

- SE-ART Tarar De Cırcuıto Cerrado

- SE-DS Piedras Gravity Selector

- SE-DC Separador De Pıedra

- SE-TR Trıeur

- SE-IS Pulidora Horizontal

- SE-DT Acondıcoınador De Inclınado

- SE-DWTR Recocido De Trigo Triple

- SE-RA Separador de Aire Cônico

- SE-SO Pulidora para Grano Húmedo

- SE-MK Separador De Basura De Alta Capacidad

- SE-MMF Fraccıon Mıxta, Clasıfıcador Seperador Depıedras Mutınator

- SE-MXM Imán Cuadrado

- SE-LP Ventılador De Baja Presıon

- Molienda

- SE-QP TAMIZ CUADRADO

- SE-TCS PLANCHISTER PEQUEÑO

- SE-SCS UNA HABİTACİON PLANCHISTER PEQUEÑO

- SE-CS TAMIZ OSCILATORIO DE CONTROL

- SE-PR PURIFICADOR DE SÉMOLA

- SE-RM MÁQUINA DE VALS

- SE-HV PLANCHISTER VIBROTORIO HORIZONTAL

- SE-BF CEPILLO DEL SALVADO

- SE-DD TAMBOR DETASOR

- SE-İD TRITURADORA DE SÉMOLA

- SE-VF VIBRO ALIMENTADOR

- SE-HP VENTILADOR DE ALTO PRESIÓN

- SE-VS VIBRO SILO EYECTOR

- SE-AT MÁQUINA ÁLGEBRA DE TEMPLE

- SE-İD DESTRUCTOR DE INFESTACION DE HARINA

- SE-SU UNİDAD DE ESTİRAMİENTO

- SE-VMD MÁQUINA DE VITAMINA

- SE-DD Silo Dischanger for Flou

- Manejo

- SE-AC CICLÓN AIRLOCK

- SE-EC AIRLOCK

- SE-BW BLOVER

- SE-CC TRANSPORTADOR MATERIA PRIMA

- SE-TS TRANSPORTADOR TUBO HELICE

- SE-CY CICLÓN

- SE-PL VALVULAS NEUMÁTICAS

- SE-AJ JET FILTRO

- SE-FSC LÍNEA DE TRANSPORTE DE PRODUCTO

- SE-MS MONO CICLÓN

- SE-SG COMPUERTA HORIZONTAL

- SE-SC TRANSPORTADOR HELICE

- SE-BE ELEVADOR

- SE-SFF CUADRADA FILTRO

- SE-ZE Z ELEVADOR

- Escala y Empaque

- SE-MP 5-10 KG MÁQUINA DE EMBALAJE AUTOMÁTICO

- SE-MP 25-50 KG MÁQUINA DE EMBALAJE AUTOMÁTICO

- SE-FM 25-50 KG MÁQUINA DE EMBALAJE AUTOMÁTICO

- SE-AH ESCALA DE GRANO

- SE-EH BASCULA DE PUENTE DE EFICIENCIA

- SE-FB MAQUINA AUTOMATICA DE DOSIFICACION

- SE-BC MÁQUINA DE EMBALAJE CAROUSEL

- SE-ZX distribuidor de harina

- SE-VTM Máquina de ensacado de harina tipo válvula

- Pieza de recambio

- Automatizacion electrica

- Molienda de harina proyectos

- 45 Toneladas en 24 Horas Molienda de harina

- 60 Toneladas en 24 Horas Molienda de harina

- 100 Toneladas en 24 Horas Molienda de harina

- 150 Toneladas en 24 Horas Molienda de harina

- 200 Toneladas en 24 Horas Molienda de harina

- 250 Toneladas en 24 Horas Molienda de harina

- 300 Toneladas en 24 Horas Molienda de harina

- Tubo De Flujo De Harina

- Proyectos de Fábricas de Acero

- Silos de Harina y Trigo

- Sección de Limpieza

- FRANÇAIS

- Section de Nettoyage

- SE-MK Aimant Tubulaire

- SE-GS Nettoyeur Séparateur

- SE-SS Nettoyeur Separateur (Simon)

- SE-AC Canal d’air

- SE-ART Tarare à recyclage d’air

- SE-DS Epierreur

- SE-DC Epierreur Classifieur

- SE-TR Trieur

- SE-IS Brosse à blé

- SE-DT Mouilleur Intensif

- SE-DWTR Trio de Recuit de Blé İntense

- SE-RA Séparateur Conique

- SE-SO Éplucheur de Coquille de Blé Turbo

- SE-MK Séparateur de Déchets de Blé Turbo

- SE-MMF Séparateur de pierre classificateur

- SE-MXM Aimant Carré

- SE-LP Aspiration Basse Pression Modèle

- Fraisage

- SE-QP Plansichter

- SE-TCS Plansıchter De Surete Au Passage Uinque

- SE-SCS Fort Control Plansifter

- SE-CS Control Plansifter

- SE-PR Sasseur

- SE-RM Appareil A Cylindres

- SE-HV La Bluterıe Vıbrante Horızontale

- SE-BF Brosse A Son

- SE-DD Detacheur A Tambour

- SE-İD Detacheur A Percussion

- SE-VF Goulotte Doseuse Vibrante

- SE-HP Aspiration Haute Pression Modèle

- SE-VS Vibro Brosse Verticale

- SE-AT Mouilleur Intensif

- SE-İD Désinsectiseur Modèle

- SE-SU Appareıl D’Etırement De Le Soıe

- SE-VMD Dosage de machine de vitamine

- SE-DD Appareil Extracteur

- Manipulation

- SE-AC L´Écluse D´Aır Cyclone

- SE-EC L´Écluse

- SE-BW Blover

- SE-CC Transporteur À Chaîne

- SE-TS Vis tubulaire Modèle

- SE-CY Cyclone Modèle

- SE-PL Aiguillage Pneumatique

- SE-AJ Filtre A Jet D’air

- SE-FSC La Lıgne De Transport Du Produıt

- SE-MS Mono Siklon

- SE-SG Vanne à Glissière Modèle

- SE-SC Transporteur A Vis Helecoidale

- SE-BE Élévateur À Godets

- SE-SFF Filtre Carré

- SE-ZE Z Élévateur

- Échelle et Émballage

- SE-MP 5-10 KG Station d’ensachage une bouche Modèle

- SE-MP 25-50 KG Station d’ensachage une bouche Modèle

- SE-FM Station d’ensachage double bouche Modèle

- SE-AH Balance de circuit Modèle

- SE-EH Balance de Rendement

- SE-FB Doseur Pondéral Modèle

- SE-BC Station d’ensachage carousel Modèle

- SE-ZX Distributeur de Farine

- SE-VTM Flour packaging machine with single valve 10/25/50 Kg

- Pièce Détachée

- Automatisation électrique

- Moulin à farine Projets

- 45 Ton 24 Heures De Capacité Moulin à farine

- 60 Ton 24 Heures De Capacité Moulin à farine

- 100 Ton 24 Heures De Capacité Moulin à farine

- 150 Ton 24 Heures De Capacité Moulin à farine

- 200 Ton 24 Heures De Capacité Moulin à farine

- 250 Ton 24 Heures De Capacité Moulin à farine

- 300 Ton 24 Heures De Capacité Moulin à farine

- Tuyaux d’écoulement

- Projets d’usine Sidérurgique

- Silos à farine et blé

- Section de Nettoyage

- العربيه

- قسم التنظيف

- SE-MK المغناطيس الانبوبي

- SE-GS آلة فرز المھملات

- SE-SS الغربيل الاهتزازي

- SE-AC قنات الھواء

- SE-ART ماسح الرادیال

- SE-DS عزالة الحصى

- SE-DC عزالة الحصى ذات الطابقين

- SE-TR جهاز فصل الشوائب

- SE-IS مقشر الحبوب الافقي

- SE-DT آلة الترطیب المزوي

- SE-DWTR مرطب القمح الثلاثي

- SE-RA شافطة مستديرة

- SE-SO مقشر الحبوب الافقي السريع

- SE-MK الغربال السريع

- SE-MMF ملتيناتور كومبينت

- SE-MXM المغناطيس المربع

- SE-LP شفاطة الغبار

- قسم الطحن

- SE-QP غربال المربع

- SE-TCS منخل التحكم

- SE-SCS منخل التحكم

- SE-CS منخل التحكم

- SE-PR مُنقية السميد

- SE-RM ماكنة الطحن نوع سيريز

- SE-HV المنخل الاهتزازي

- SE-BF ماكنة تخليص النخالة

- SE-DD ماكنة الفرز الاسطوانية

- SE-İD ماكنة فصل السميد

- SE-VF المغذي الاهتزازي

- SE-HP مروحة الضغط الواطئ

- SE-VS منخل ویبرو

- SE-AT جهاز الترطيب التلقائي

- SE-İD قاتل حشرات

- SE-SU آلة تمتد الحرير

- SE-VMD آلة فيتامين

- SE-DD روتوفلو

- قسم النقل

- SE-AC قفل الهواءسايكلون

- SE-EC الاكليز الهواء

- SE-BW ضاغط الهواء

- SE-CC الناقل السلسلي

- SE-TS الناقل الانبوبي

- SE-CY سايكلون الاتربة

- SE-PL محول اتجاه ضغط الهواء العالي

- SE-AJ المرشح النفاث

- SE-FSC ناقل الطحين الحلزوني

- SE-MS أحادية الإعصار

- SE-SG رفرف التمرير

- SE-SC الناقل الحلزوني

- SE-BE رافعة الطوس

- SE-SFF مرشح مربع

- SE-ZE نوع السلسلة مصعد دلو عمودي

- قسم التعبئة

- SE-MP 1 تعبئة وتغليف الطحين ٥كغ و١٠كغ

- SE-MP 2 تعبئة وتغليف الطحين ٢٥كغ و٥٠كغ

- SE-FM جهاز تعبئة بفوهة مفردة وميزان مفرد

- SE-AH مقياس الكفائة المربع

- SE-EH مقياس الكفائة الدائري

- SE-FB موازن الجريان

- SE-BC جهاز تعبئة الطحين ذو ٤ فتحات وذو ٦ فتحات

- SE-ZX موزع الطحين الدوار

- SE-VTM آلة تعبئة وتغليف الدقيق من نوع صمام

- قطع الغيار

- النظام الكهربائي

- الأنظمة بتسلیم المفتاح

- انابيب معامل الطحين

- مشاريع بناء معامل الطحين

- سايلوات الحنطة والطحين

- قسم التنظيف

- DEUTSCH

- Contact

- CATALOGS & КАТАЛОГИ

- РУССКИЙ

- Очистительная линия

- SE-MK Трубчатый магнит

- SE-GS Зерновой сепаратор

- SE-SS Зерновой сепаратор Saymn

- SE-AC Аспирационный канал

- SE-ART Тарар с рециркуляцией воздуха

- SE-DS Камнеотборник

- SE-DC Камнеотборник 2 этажный

- SE-TR Триер

- SE-IS Oбоечная машина

- SE-DT Вихревой увлажнитель

- SE-DWTR Увлажнительная машина

- SE-RA Круговои ceпаратор

- SE-SO Обоечная машина Turbo

- SE-MK Cепаратор высокого объема

- SE-MMF Multinator кaмнeoтбoрник

- SE-MXM Kвадратный Mагнит

- SE-LP Вентилятор низкого давления

- Размольная линия

- SE-QP Квадратный рассев

- SE-TCS Малогабаритный рассев

- SE-SCS Подвесной контрольный рассев

- SE-CS Напольный раскачивающийся контрольный рассев

- SE-PR Ситовеечная машина

- SE-RM Четырех- и восьмивальцовые станки

- SE-HV Горизонтальное виброционное сито

- SE-BF Вымольная машина

- SE-DD Барабанный деташер

- SE-İD Энтолейтор

- SE-VF Вибропитатель

- SE-HP Вентилятор высокого и низкого давления

- SE-VS Вертикальное вибрационное сито

- SE-AT Увлажнитель автоматический

- SE-İD Уничтожитель насекомых

- SE-SU Стол для натяжения ситоткани

- SE-VMD Bитаминизатор

- SE-DD Виброразгрузитель для муки, зерна и отрубей

- Раздел траспортировки

- SE-AC Шлюзовый затвор и циклон

- SE-EC Эклюс

- SE-BW Бловер

- SE-CC Транспортёр цепной в коробе

- SE-TS Трубчатый винтовой конвейер

- SE-CY Пылевой циклон

- SE-PL Клапан перекидной

- SE-AJ Фильтры

- SE-FSC Линия по перевозке продукта

- SE-MS Моно Циклон

- SE-SG Пневматический и мануальный затвор

- SE-SC Шнековый конвейер

- SE-BE Элеватор

- SE-SFF Квадратный фильтр

- SE-ZE Z образная нория

- Фасовочная линия

- SE-MP Упаковочная машина на 5,10 кг мука пакет

- SE-MP Упаковочная машина на 25,50 кг пакет мука

- SE-FM Упаковочная машина на 25,50 кг пакет мука однократное наполнение и двойное опустошение

- SE-AH Поточные весы

- SE-EH Цилиндрические поточные весы

- SE-FB Дозатор зерна

- SE-BC Упаковочная машина для муки карусельного типа

- SE-ZX Распределитель муки

- SE-VTM Клапанная система погрузки в мешки

- Машины для комбикормовых заводов

- Запасные части

- Электрическая автоматизация

- Проекты мукомольных заводов

- Монтажное оборудование

- Здания из стальных конструкций

- Cилосы для муки и зерна

- Очистительная линия

- English

- Cleaning section

- SE-MK Magnet Tubular Type

- SE-GS Grain Seperator

- SE-SS Saymn Seperator

- SE-AC Air Canal

- SE-ART Air Recycling Tarar

- SE-DS Dry Stoner

- SE-DC Destoner Classifier

- SE-TR Trieur

- SE-IS Intensive Scourer

- SE-DT Dampener Turbolizer

- SE-DWTR Dampener With There Rotor

- SE-RA Round Aspırator

- SE-SO Scourer

- SE-MK Heavy Cleaning Separator

- SE-MMF Multınator Mıxed Flactıon-CalssIfler Destoner

- SE-MXM Square Magnet

- SE-LP Low Pressure Fan

- Milling Section

- SE-QP Quadro Plansifter

- SE-TCS Two Channel Sifter

- SE-SCS Single Channel Sifter

- SE-CS Control Sifter

- SE-PR Purifier

- SE-RM Roller Mill

- SE-HV Horızontal Vıbro Sıfter

- SE-BF Bran Finisher

- SE-DD Drum Detacher

- SE-İD Impact Detacher

- SE-VF Vibro Feeder

- SE-HP High Pressure Fan

- SE-VS Vibro Sifter

- SE-AT Automatic Tempering Machine

- SE-İD Infestation Destroyer For Flour

- SE-SU Stretching Unit

- SE-VMD Vitamin Machine Dosing

- SE-DD Drum Dıscharger For Flour and Bran

- Transportation Group

- SE-AC Aırlock And Pneumatıc Cyclone

- SE-EC Ecluse

- SE-BW Blover

- SE-CC Chain Conveyor

- SE-TS Tubular Screw Conveyor

- SE-CY Cyclone

- SE-PL Pneumatic Line Diverting Gate

- SE-AJ Air Jet Plus Filter

- SE-FSC Flour Screw Conveyor

- SE-MS Mono Siklon

- SE-SG Slıdıng Gate

- SE-SC Screw Conveyor

- SE-BE Bucket Elevatör

- SE-SFF Square Filter

- SE-ZE Z Elevatör

- Packing Section

- SE-MP 1 Mouth Packing Machine 5 kg – 10 kg

- SE-MP 1 Mouth Packing Machine 25 kg – 50 kg

- SE-FM Flour Bagging Machine System With Double Weigh Hopper & Single Station 25/50 Kg

- SE-AH Automatic Hopper Scale

- SE-EH Extraction Rate Scale

- SE-FB Flow Balancer

- SE-BC Bagging Carousel

- SE-ZX flour distributor

- SE-VTM Valve Type Flour Bagging Machine

- Spare Part

- Electrical Automation

- Flour Factory Projects

- Flour Flow Pipe

- Steel Factory Projects

- Flour and Wheat Silos

- Cleaning section

- ESPAÑOL

- Sección de Limpieza

- SE-MK Aparato Magnético Tubular

- SE-GS Vıbro Sılo Eyecyor

- SE-SS Separador Saymn

- SE-AC Separador Aerodinámico

- SE-ART Tarar De Cırcuıto Cerrado

- SE-DS Piedras Gravity Selector

- SE-DC Separador De Pıedra

- SE-TR Trıeur

- SE-IS Pulidora Horizontal

- SE-DT Acondıcoınador De Inclınado

- SE-DWTR Recocido De Trigo Triple

- SE-RA Separador de Aire Cônico

- SE-SO Pulidora para Grano Húmedo

- SE-MK Separador De Basura De Alta Capacidad

- SE-MMF Fraccıon Mıxta, Clasıfıcador Seperador Depıedras Mutınator

- SE-MXM Imán Cuadrado

- SE-LP Ventılador De Baja Presıon

- Molienda

- SE-QP TAMIZ CUADRADO

- SE-TCS PLANCHISTER PEQUEÑO

- SE-SCS UNA HABİTACİON PLANCHISTER PEQUEÑO

- SE-CS TAMIZ OSCILATORIO DE CONTROL

- SE-PR PURIFICADOR DE SÉMOLA

- SE-RM MÁQUINA DE VALS

- SE-HV PLANCHISTER VIBROTORIO HORIZONTAL

- SE-BF CEPILLO DEL SALVADO

- SE-DD TAMBOR DETASOR

- SE-İD TRITURADORA DE SÉMOLA

- SE-VF VIBRO ALIMENTADOR

- SE-HP VENTILADOR DE ALTO PRESIÓN

- SE-VS VIBRO SILO EYECTOR

- SE-AT MÁQUINA ÁLGEBRA DE TEMPLE

- SE-İD DESTRUCTOR DE INFESTACION DE HARINA

- SE-SU UNİDAD DE ESTİRAMİENTO

- SE-VMD MÁQUINA DE VITAMINA

- SE-DD Silo Dischanger for Flou

- Manejo

- SE-AC CICLÓN AIRLOCK

- SE-EC AIRLOCK

- SE-BW BLOVER

- SE-CC TRANSPORTADOR MATERIA PRIMA

- SE-TS TRANSPORTADOR TUBO HELICE

- SE-CY CICLÓN

- SE-PL VALVULAS NEUMÁTICAS

- SE-AJ JET FILTRO

- SE-FSC LÍNEA DE TRANSPORTE DE PRODUCTO

- SE-MS MONO CICLÓN

- SE-SG COMPUERTA HORIZONTAL

- SE-SC TRANSPORTADOR HELICE

- SE-BE ELEVADOR

- SE-SFF CUADRADA FILTRO

- SE-ZE Z ELEVADOR

- Escala y Empaque

- SE-MP 5-10 KG MÁQUINA DE EMBALAJE AUTOMÁTICO

- SE-MP 25-50 KG MÁQUINA DE EMBALAJE AUTOMÁTICO

- SE-FM 25-50 KG MÁQUINA DE EMBALAJE AUTOMÁTICO

- SE-AH ESCALA DE GRANO

- SE-EH BASCULA DE PUENTE DE EFICIENCIA

- SE-FB MAQUINA AUTOMATICA DE DOSIFICACION

- SE-BC MÁQUINA DE EMBALAJE CAROUSEL

- SE-ZX distribuidor de harina

- SE-VTM Máquina de ensacado de harina tipo válvula

- Pieza de recambio

- Automatizacion electrica

- Molienda de harina proyectos

- 45 Toneladas en 24 Horas Molienda de harina

- 60 Toneladas en 24 Horas Molienda de harina

- 100 Toneladas en 24 Horas Molienda de harina

- 150 Toneladas en 24 Horas Molienda de harina

- 200 Toneladas en 24 Horas Molienda de harina

- 250 Toneladas en 24 Horas Molienda de harina

- 300 Toneladas en 24 Horas Molienda de harina

- Tubo De Flujo De Harina

- Proyectos de Fábricas de Acero

- Silos de Harina y Trigo

- Sección de Limpieza

- FRANÇAIS

- Section de Nettoyage

- SE-MK Aimant Tubulaire

- SE-GS Nettoyeur Séparateur

- SE-SS Nettoyeur Separateur (Simon)

- SE-AC Canal d’air

- SE-ART Tarare à recyclage d’air

- SE-DS Epierreur

- SE-DC Epierreur Classifieur

- SE-TR Trieur

- SE-IS Brosse à blé

- SE-DT Mouilleur Intensif

- SE-DWTR Trio de Recuit de Blé İntense

- SE-RA Séparateur Conique

- SE-SO Éplucheur de Coquille de Blé Turbo

- SE-MK Séparateur de Déchets de Blé Turbo

- SE-MMF Séparateur de pierre classificateur

- SE-MXM Aimant Carré

- SE-LP Aspiration Basse Pression Modèle

- Fraisage

- SE-QP Plansichter

- SE-TCS Plansıchter De Surete Au Passage Uinque

- SE-SCS Fort Control Plansifter

- SE-CS Control Plansifter

- SE-PR Sasseur

- SE-RM Appareil A Cylindres

- SE-HV La Bluterıe Vıbrante Horızontale

- SE-BF Brosse A Son

- SE-DD Detacheur A Tambour

- SE-İD Detacheur A Percussion

- SE-VF Goulotte Doseuse Vibrante

- SE-HP Aspiration Haute Pression Modèle

- SE-VS Vibro Brosse Verticale

- SE-AT Mouilleur Intensif

- SE-İD Désinsectiseur Modèle

- SE-SU Appareıl D’Etırement De Le Soıe

- SE-VMD Dosage de machine de vitamine

- SE-DD Appareil Extracteur

- Manipulation

- SE-AC L´Écluse D´Aır Cyclone

- SE-EC L´Écluse

- SE-BW Blover

- SE-CC Transporteur À Chaîne

- SE-TS Vis tubulaire Modèle

- SE-CY Cyclone Modèle

- SE-PL Aiguillage Pneumatique

- SE-AJ Filtre A Jet D’air

- SE-FSC La Lıgne De Transport Du Produıt

- SE-MS Mono Siklon

- SE-SG Vanne à Glissière Modèle

- SE-SC Transporteur A Vis Helecoidale

- SE-BE Élévateur À Godets

- SE-SFF Filtre Carré

- SE-ZE Z Élévateur

- Échelle et Émballage

- SE-MP 5-10 KG Station d’ensachage une bouche Modèle

- SE-MP 25-50 KG Station d’ensachage une bouche Modèle

- SE-FM Station d’ensachage double bouche Modèle

- SE-AH Balance de circuit Modèle

- SE-EH Balance de Rendement

- SE-FB Doseur Pondéral Modèle

- SE-BC Station d’ensachage carousel Modèle

- SE-ZX Distributeur de Farine

- SE-VTM Flour packaging machine with single valve 10/25/50 Kg

- Pièce Détachée

- Automatisation électrique

- Moulin à farine Projets

- 45 Ton 24 Heures De Capacité Moulin à farine

- 60 Ton 24 Heures De Capacité Moulin à farine

- 100 Ton 24 Heures De Capacité Moulin à farine

- 150 Ton 24 Heures De Capacité Moulin à farine

- 200 Ton 24 Heures De Capacité Moulin à farine

- 250 Ton 24 Heures De Capacité Moulin à farine

- 300 Ton 24 Heures De Capacité Moulin à farine

- Tuyaux d’écoulement

- Projets d’usine Sidérurgique

- Silos à farine et blé

- Section de Nettoyage

- العربيه

- قسم التنظيف

- SE-MK المغناطيس الانبوبي

- SE-GS آلة فرز المھملات

- SE-SS الغربيل الاهتزازي

- SE-AC قنات الھواء

- SE-ART ماسح الرادیال

- SE-DS عزالة الحصى

- SE-DC عزالة الحصى ذات الطابقين

- SE-TR جهاز فصل الشوائب

- SE-IS مقشر الحبوب الافقي

- SE-DT آلة الترطیب المزوي

- SE-DWTR مرطب القمح الثلاثي

- SE-RA شافطة مستديرة

- SE-SO مقشر الحبوب الافقي السريع

- SE-MK الغربال السريع

- SE-MMF ملتيناتور كومبينت

- SE-MXM المغناطيس المربع

- SE-LP شفاطة الغبار

- قسم الطحن

- SE-QP غربال المربع

- SE-TCS منخل التحكم

- SE-SCS منخل التحكم

- SE-CS منخل التحكم

- SE-PR مُنقية السميد

- SE-RM ماكنة الطحن نوع سيريز

- SE-HV المنخل الاهتزازي

- SE-BF ماكنة تخليص النخالة

- SE-DD ماكنة الفرز الاسطوانية

- SE-İD ماكنة فصل السميد

- SE-VF المغذي الاهتزازي

- SE-HP مروحة الضغط الواطئ

- SE-VS منخل ویبرو

- SE-AT جهاز الترطيب التلقائي

- SE-İD قاتل حشرات

- SE-SU آلة تمتد الحرير

- SE-VMD آلة فيتامين

- SE-DD روتوفلو

- قسم النقل

- SE-AC قفل الهواءسايكلون

- SE-EC الاكليز الهواء

- SE-BW ضاغط الهواء

- SE-CC الناقل السلسلي

- SE-TS الناقل الانبوبي

- SE-CY سايكلون الاتربة

- SE-PL محول اتجاه ضغط الهواء العالي

- SE-AJ المرشح النفاث

- SE-FSC ناقل الطحين الحلزوني

- SE-MS أحادية الإعصار

- SE-SG رفرف التمرير

- SE-SC الناقل الحلزوني

- SE-BE رافعة الطوس

- SE-SFF مرشح مربع

- SE-ZE نوع السلسلة مصعد دلو عمودي

- قسم التعبئة

- SE-MP 1 تعبئة وتغليف الطحين ٥كغ و١٠كغ

- SE-MP 2 تعبئة وتغليف الطحين ٢٥كغ و٥٠كغ

- SE-FM جهاز تعبئة بفوهة مفردة وميزان مفرد

- SE-AH مقياس الكفائة المربع

- SE-EH مقياس الكفائة الدائري

- SE-FB موازن الجريان

- SE-BC جهاز تعبئة الطحين ذو ٤ فتحات وذو ٦ فتحات

- SE-ZX موزع الطحين الدوار

- SE-VTM آلة تعبئة وتغليف الدقيق من نوع صمام

- قطع الغيار

- النظام الكهربائي

- الأنظمة بتسلیم المفتاح

- انابيب معامل الطحين

- مشاريع بناء معامل الطحين

- سايلوات الحنطة والطحين

- قسم التنظيف

- DEUTSCH

- Contact

- CATALOGS & КАТАЛОГИ

© 2024 SEDİROGLU. Created for free using WordPress and

Colibri

Flour and Feed Mill Machines

SE-AJ Air Jet Plus Filter

© 2024 SEDİROGLU. Created for free using WordPress and

Colibri